AISC Certified Steel Fabrication Shop

The team at Revolution Industrial is proud of our state-of-the-art steel fabrication shop, which spans 13 acres and 159,000 square feet. Within our expansive facilities, we utilize cutting-edge technology, industry-leading processes and equipment, and decades of expertise to deliver top-quality steel fabrication that meets project needs of varying scales and complexities.

Steel Fabrication Services

We offer a comprehensive range of AISC-certified steel fabrication services to cater to a wide range of project requirements. Whether you need structural steel, hand rails, piping systems, or commercial construction materials, we have the capabilities to fulfill your specifications with precision and accuracy. From initial design concepts to final fabrication and delivery, we are committed to providing end-to-end solutions that meet your timelines and budget constraints.

CNC Fabrication

Our top-of-the-line CNC machinery ensures precision and efficiency in every project we undertake. By sequencing large projects, we’re able to streamline projects to get ahead of schedule without sacrificing quality.

Handrail Fabrication

Our Bend Tech Dragon A400 allows us to efficiently fabricate high-quality steel, aluminum, stainless steel, chrome alloy, and galvanized steel handrails with accurate scribe lines and clean, tight fits for projects across industry sectors.

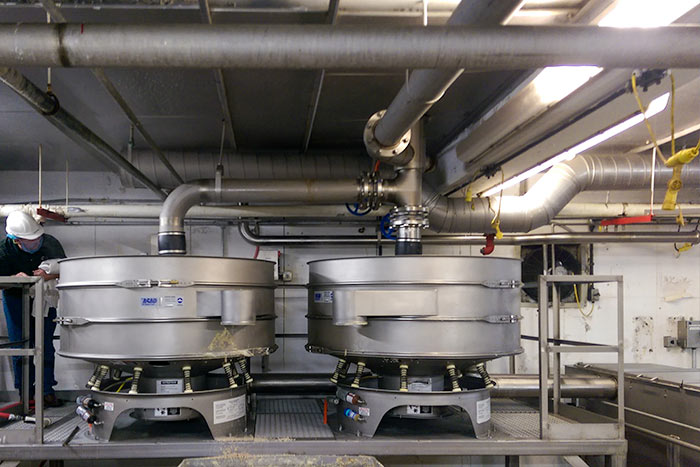

Piping Systems

Our shop has capabilities to meet project specifications across industries, including oil & gas, water & wastewater, and more. Our team successfully completes projects of all sizes and complexities, on time and within budget.

Structural Steel

We provide AISC-certified structural steel fabrication services to a range of industrial and commercial markets, facilitating faster construction, easier installation, and reduced project costs. Our team has delivered quality structural steel on many diverse project types over the years.

Tanks & Vessels

We work with our clients to provide the best solutions for their vessel fabrication needs. From design to fabrication, coating, testing, and delivery, we’re focused on quality and compliance as well as safety and cost-effectiveness on every project.

Miscellaneous Fabrication

With a state-of-the-art facility and skilled, experienced teams, we can fabricate nearly anything your project requires. Give us a call to find out how we can accommodate your next project.

Quality Assurance

We prioritize quality in all aspects of our work. We use high-quality materials from trusted sources and conduct rigorous tests to ensure our products meet the highest standards. Our commitment to quality control is driven by a customer-centric approach, aiming for satisfaction, reliability, and longevity. Through continuous improvement and feedback, we surpass industry benchmarks. Our dedication to quality has earned us industry certifications and awards, and we remain focused on delivering unmatched quality, reliability, and safety for our customers’ satisfaction.

Our Fabrication Team

Our success relies on a skilled team committed to maintaining and enhancing product quality. Our engineers, welders, fabricators, and technicians are highly trained in steel fabrication, consistently delivering superior products above industry standards. As an AISC-certified shop, we prioritize error prevention and consistent results through routine audits and inspections. Each employee understands their role in ensuring high-quality, cost-effective steel products for our clients, minimizing re-work.

Our Fabrication Capabilities

EMI ACPC

Shape Line

Victory

Plasma Machine

Bend Tech Dragon A400

Maximum Material Length 24’

Shop

Equipment

BAYLYNX

Cambering Machine

7L Bending Roll

(Webb Roll)

Get in Touch

At Revolution Industrial, we are dedicated to excellence in everything we do. Whether it’s delivering superior products, providing exceptional customer service, or fostering a culture of continuous improvement, we strive to exceed expectations and build lasting relationships with our clients. When you choose Revolution Industrial for your steel fabrication needs, you can trust us to deliver results that meet the highest standards of quality and craftsmanship.